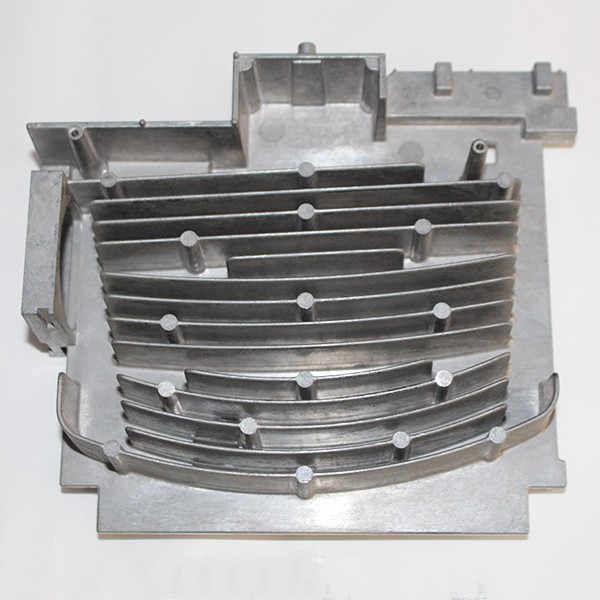

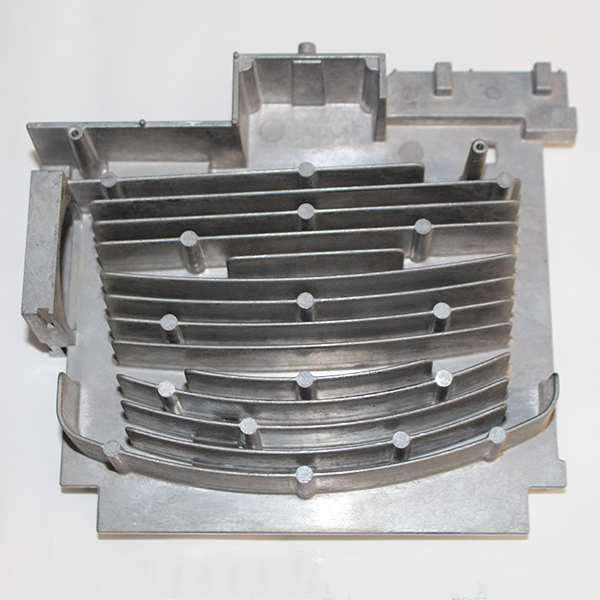

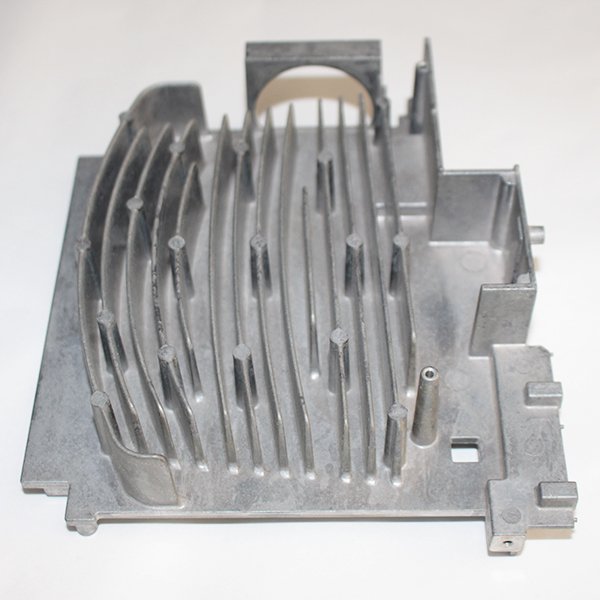

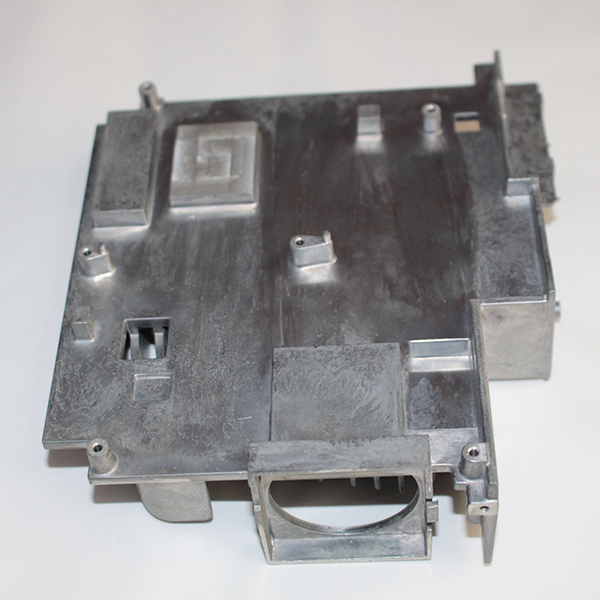

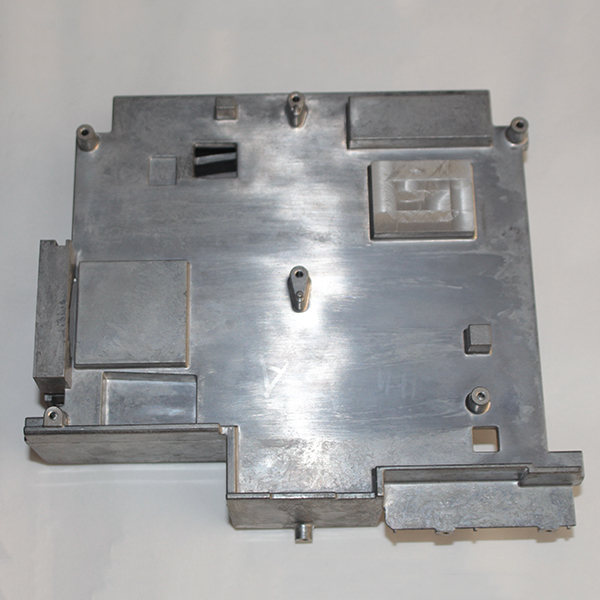

Metal Die Cast Compound Cast Compound Machining Casting Steel Rotary Kiln Double Helical Customized Compound Hardening Module

Metal Die Cast Compound Cast Compound Machining Casting Steel Rotary Kiln Double Helical Customized Compound Hardening Module

- HRTS

- Shenzhen

- 1 week

- 50000pcs/month

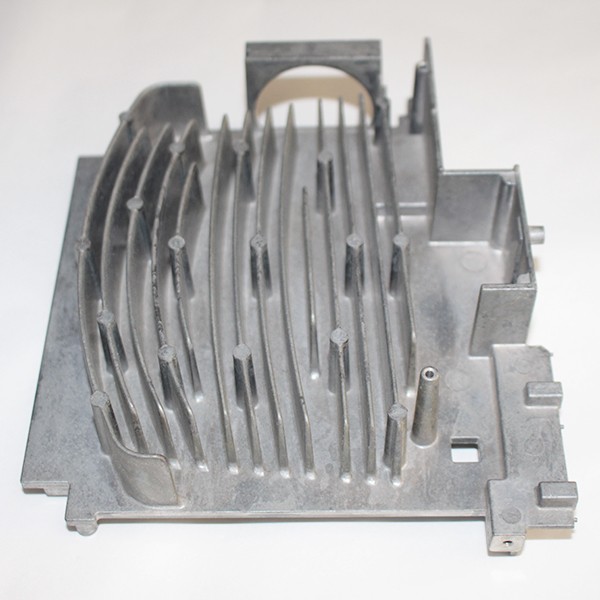

Plastic injection mold advantages:

1.Professional design team

2.Professional mold design team

3.Professional mold making machines

4.Professional mold and product QC and etc. team

5.Rich mold making experience with different clients from various country

Metal Die Cast Compound Cast Compound Machining Casting Steel Rotary Kiln Double Helical Customized Compound Hardening Mold

We specializes in manufacturing and supplying various plastic injection molds, double color molds.

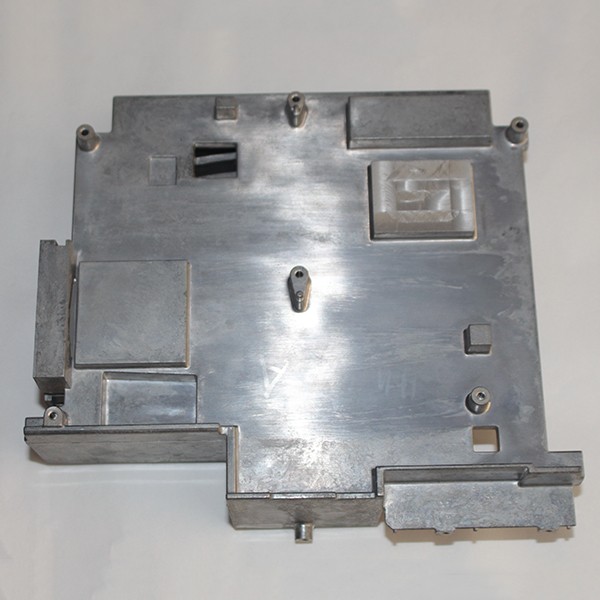

Main parameter:

Brand | HRTS |

Model | D001 |

Mold Base | LKM, HASCO, DME or your requirement |

Mold Material | 45#, P20, H13, 718, 1.2344, 1.2738 and so on |

Standard | HASCO, LKM ,DME, MISUMI, PUNCH and so on |

Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or others |

Runner | Cold/Hot Runner |

Gate Type | Side gate, Sub gate, Pin point gate, Edge gate etc |

Mould Weight | 50kg-10000Ton |

Injection Machine Type | 80-2500Ton |

Certificated | ISO 9001:2008 Certificated |

Process machings | CNC/Cutting/EMD/Milling/Drilling/Thread/Carved |

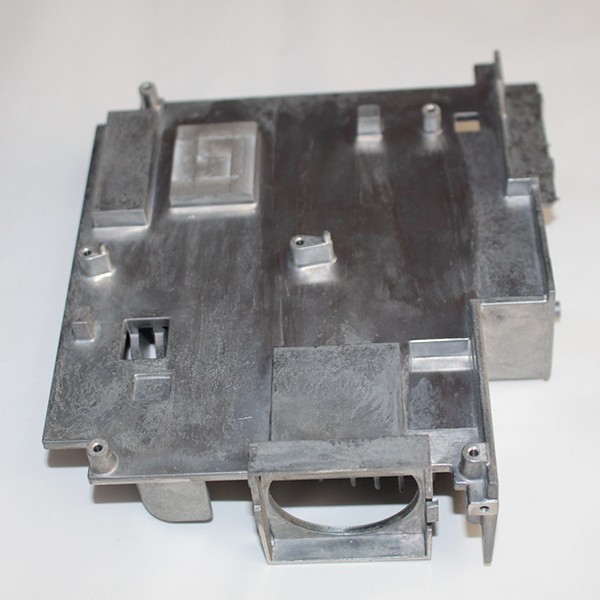

Mold Service | Plastic injection molding,Die casting mold,Sand casting ,Stamping Mold,Bending Mold,Punching ,Silicione Mold,Double Injection Mold, Extrusion Mold |

Pacakge | Rust-proof protection, fresco bag, wooden case and pallet, suitable for shipment |

Payment term | T/T,Western union, Paypal |

LEAD TIME | Samples : 5-15 days , Mold :22-30 days , Products : 10 days |

Product detail: